- WEIGH & COUNT

- Weigh Scales

& Counters

- BAG & SEAL

- Vertical Form Fill

& Seal Systems - Flow Wrapping

Machinery - Autobag Bagging

Systems - Baggers & Band Sealers

- LIQUID FILL

- Liquid Filling

Systems - Bottle Management

Systems - Depositors

- TRAY & CARTON

- Tray & Cup Fillers &

Sealers - Carton & Tray Formers

- BROWSE

- ALL CONTRACT

PACKAGING SERVICES - ABOUT QUAL PAC

- QUAL PAC CERTIFICATIONS

& REGISTRATIONS - QUAL PAC LOCATIONS

- Shrink Wrapping

Services - Shrink Bundling

Services - Blister & Clamshell

Packaging Services - Flow Wrapping

Fin Seal Services

Shuttleworth Slip-Torque Technology

- Packaging Equipment and Machines

- Conveyor Systems

- Shuttleworth Product Handling Systems

- Shuttleworth Accumulation and Buffering Systems

- Shuttleworth Engineered Conveyor Solutions

- Shuttleworth SmartFeed Wrapper & Case Packer Infeed Systems

- Shuttleworth Conveyor Devices & Options

- Shuttleworth Frame Designs

- Shuttleworth Slip-Torque Roller Surface

- Shuttleworth Slip-Torque Technology

- Shuttleworth Standard & Specialty Rollers

- Shuttleworth Surface & Design Flexibility

- Roach Conveyors

- SpanTech Conveyor Systems

- Shuttleworth Product Handling Systems

- Conveyor Systems

At a Glance

- Creates very low back-pressure

- Without jamming, scuffing or shingling products

- Highest level of safety with minimal opportunities for injury

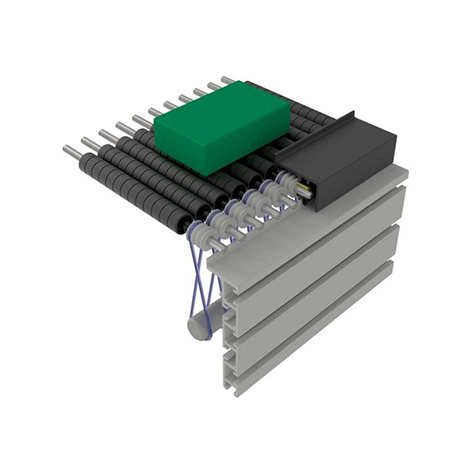

Click to enlarge

Recommended

Transport Products without Jamming, Scuffing or Shingling

Shuttleworth's innovative Slip-Torque roller technology creates very low back-pressure, enabling transport and accumulation of products without jamming, scuffing or shingling. Perfect for gentle product handling, Shuttleworth Slip-Torque roller technology offers the highest level of safety in the industry with minimal opportunities for injury risks.

Slip-Torque technology is based on polished stainless steel shafts individually powered by flexible belts on a line shaft or by a continuous chain. These stainless steel shafts are covered with segmented, loose-fit rollers, which become the conveyor surface.

The weight of the product being conveyed combined with the coefficient of friction between the shafts and the inside diameter of the rollers provide the driving force. As the weight of the product increases, there is a corresponding increase in the driving force supplied. As the product stops, the segmented rollers beneath it also stop, creating very low back-pressure accumulation and reducing product damage.

Slip-Torque Technology is based upon two factors: Individually powered roller shafts and a segmented, loose fit roller set. Power is transmitted to the roller shafts via a continuous roller chain system.

The chain drive system uses a continuous roller chain with support track and idler sprockets. The roller shafts are fitted with sprockets, which engage the drive chain. Chain drive is usually used in very oily applications, dirty conditions, and in extreme temperature conditions.

Features & Benefits

- Safe and gentle for both products and operators

- Inherent low pressure conveyance allows for mass product accumulation without damage or crushing

- Available in chain and belt driven designs

- Flexible design allows for use across a variety of industries and applications

- Over 200 engineered rollers available in a variety of diameters and materials

- Surface design allows for devices and options to be seamlessly integrated within the conveyor surface

Chain Drive Specifications | |

| Max Speed | 91.4 m/min. (300fpm) |

| Max Weight | 119 kg/m(80 lbs/ft) |

| Min Temperature | -40° C (-40°F) |

| Max Temperature | 148° C (300°F) |

| Lengths | 0.5m, 1.0m, 1.5m, 2.0m, 2.5m, 3.0m |

| Max Surface Width | Up to 1500mm |

Belt Drive Specifications | |

| Max Speed | 36.6 m/min. (120fpm) |

| Max Weight | 79 kg/m (53 lbs/ft) |

| Min Temperature | 0° C (32°F) |

| Max Temperature | 46° C (115°F) |

| Lengths | 0.5m, 1.0m, 1.5m, 2.0m, 2.5m, 3.0m |

| Max Surface Width | Up to 1500mm |

Please contact Pro Pac or call 888-318-0083 for your product handling equipment.