- WEIGH & COUNT

- Weigh Scales

& Counters

- BAG & SEAL

- Vertical Form Fill

& Seal Systems - Flow Wrapping

Machinery - Autobag Bagging

Systems - Baggers & Band Sealers

- LIQUID FILL

- Liquid Filling

Systems - Bottle Management

Systems - Depositors

- TRAY & CARTON

- Tray & Cup Fillers &

Sealers - Carton & Tray Formers

- BROWSE

- ALL CONTRACT

PACKAGING SERVICES - ABOUT QUAL PAC

- QUAL PAC CERTIFICATIONS

& REGISTRATIONS - QUAL PAC LOCATIONS

- Shrink Wrapping

Services - Shrink Bundling

Services - Blister & Clamshell

Packaging Services - Flow Wrapping

Fin Seal Services

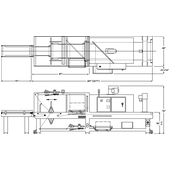

nVenia Arpac 45TW Continious Motion Tray Shrink Wrapper

- Packaging Equipment and Machines

- Shrink Bundling Equipment

- Polypack Shrink Bundling Systems

- nVenia Arpac Shrink Bundling Equipment

- nVenia Arpac Shrink Bundling Systems

- nVenia Arpac Tray Shrink Bundling Systems

- nVenia Arpac 25TW Intermittent Motion Tray Shrink Wrapper

- nVenia Arpac 75LTW Continuous Motion Tray Wrapper

- nVenia Arpac 45TW Continious Motion Tray Shrink Wrapper

- nVenia Arpac 65TW Tray Shrink Wrapper

- nVenia Arpac Brandpac Shrink Bundling Systems

- nVenia Arpac Heat Shrink Tunnels

- Eastey Shrink Bundling Equipment

- Heat Seal Shrink Bundling Equipment

- Kayat Continuous-Motion Shrink Bundling Equipment

- Shrink Bundling Equipment

At a Glance

- Continuous motion tray bundler

- Designed for trayed cartons, bottles, and cans

- Wraps up to 45 products per minute

- Around-the-clock reliability

Buy your shrink bundling film from Pro Pac, and get a discount on this Arpac tray wrapper!

Click to enlarge

Recommended

Continuous Motion Tray Bundler Wrapping Up to 45 Trays per Minute

The nVenia Arpac 45TW tray wrapper is part of a dependable line of shrink packaging systems designed to service a wide variety of industries. This compact and economical shrink wrapper is capable of wrapping up to 45 products per minute, depending on product size.

This system will wrap any unitized or tray-packed product, including random pack sizes. The 45TW tray wrapper guarantees years of reliable service, and is ready to ship in as little as two weeks from the order date.

Mode of Operation

- The system operation begins when products (broad-side leading) transfer from the customer's production line onto the in-feed pacing conveyor of the wrapper.

- This in-feed pacing conveyor will create the required pacing of the products for the wrapping cycle.

- The trays will now intersect the film web and pass through the seal frame.

- When the trailing edge of the product passes through the seal frame the seal bars will close and follow the product.

- The dwell timer times out and the seal bars open forming a sleeve of film around the product.

- The sleeved product then conveys into and through the tunnel chamber tunnel where the combination of heat and air flow shrink the film sleeve around the product to form a tight neat package.

- The bundle now exits the tunnel and passes through a three-way air cooling section and transfers onto the customer's conveyor to complete the shrink overwrap packaging cycle.

- Heavy-duty rugged construction designed for high durability and around-the-clock operation

- Laser cut and CNC machined components for maximum precision

- Powder coat finish that provides a durable scratch resistant surface and prevents corrosion

- Allen-Bradley PanelView 600Plus operator interface with color touchscreen, message display and self-diagnostics

- Digital controls for fast and accurate setup when changing product size and film

- Bypass mode allows product to pass through the machine without being wrapped and without heating the tunnel

- 6' infeed belt conveyor for product pacing

- Durable Intralox conveyor belts eliminate tracking problems

- Continuous-motion telescoping infeed, seal conveyor and carriage for optimum speed and performance

- Manual-film splicing bar for quick and easy film changeovers

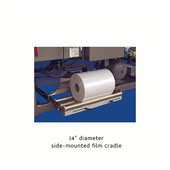

- 14" diameter side mounted film cradles for easy film loading

- 70" single zone shrink tunnel

- 3-way cooling feature at the tunnel exit for immediate product handling

- NEMA 12 electrical cabinet and controls

- Central point lubrication simplifies preventative maintenance

- Low film alert warns that a film changeover will soon be necessary

- All working areas are guarded with clear polycarbonate hinged doors with electrical interlocks

- Powder coated finish is standard

- Casters for machine portability

- Quick-change seal frame cylinder kit for higher speeds

- Jib crane to assist with film loading

- Dual film cradle for quick film changeover

- 20" film roll diameter capacity

- Alternate voltages available: 208VAC, 220VAC, 575VAC

- Print registration – top film only

- Seal gap bridge, roller or telescoping, for product 3"-6" long

- Cans

- Plastic bottles

- Jars

- Glass bottles

- Floor tiles

- Plates

- Cartons

- Speed: Up to 45 trays per minute

- Electrical: 460 VAC, 3 Ph, 60 Hz, 48 A

- Air: 80 psi, 30 SCFM<>/dd>

- Width (across machine): 6" to 18"

- Length (flow direction): 6" to 15"

- Height: 2" to 12"

- Roll Diameter: 14"

- Gauge: 3 mil

- Roll Width: 27"

- Type: Low density polyethylene (LDPE)

- Clear or randomly printed

Features

Guarding and Finish

Options

Example Products

Machine Specifications

Product Specifications

Film Specifications

Please contact Pro Pac or call 888-318-0083 for your shrink bundling equipment.