- WEIGH & COUNT

- Weigh Scales

& Counters

- BAG & SEAL

- Vertical Form Fill

& Seal Systems - Flow Wrapping

Machinery - Autobag Bagging

Systems - Baggers & Band Sealers

- LIQUID FILL

- Liquid Filling

Systems - Bottle Management

Systems - Depositors

- TRAY & CARTON

- Tray & Cup Fillers &

Sealers - Carton & Tray Formers

- BROWSE

- ALL CONTRACT

PACKAGING SERVICES - ABOUT QUAL PAC

- QUAL PAC CERTIFICATIONS

& REGISTRATIONS - QUAL PAC LOCATIONS

- Shrink Wrapping

Services - Shrink Bundling

Services - Blister & Clamshell

Packaging Services - Flow Wrapping

Fin Seal Services

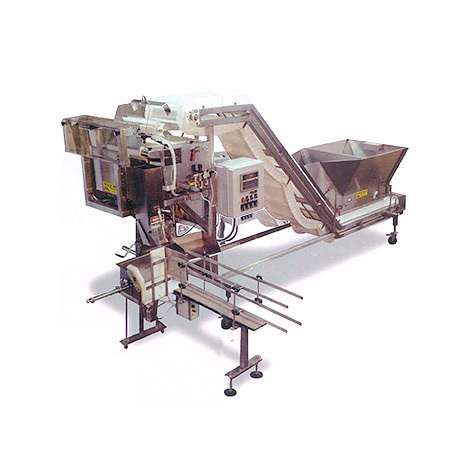

Weigh Right FCS Series Fresh-Cut Vegetable Filler

- Packaging Equipment and Machines

- Weighing & Counting Equipment

- Ohlson Weighing, Filling & Counting Systems

- Weigh Right Weighing, Filling & Counting Systems

- Weigh Right Net Weigh Scales

- Weigh Right PMB Series Standard Vibratory Scale

- Weigh Right Large-Volume Bulk Weigh Scales

- Weigh Right High-Speed Low-Cost Weigh Scales

- Weigh Right FCS Series Fresh-Cut Vegetable Filler

- Weigh Right PMB-F Series Fresh-Cut Fruit Filler

- Weigh Right BDC Series Belt Feed Moist Product Scale

- Weigh Right HF-1 Hand Feed Scale

- Weigh Right iQ-1E Entry Level Scale

- Weigh Right SDS Short Drop Scale Tray Filler

- Weigh Right G-50 Series Direct Fill Gross Weight Scale

- Weigh Right A Series Volumetric Filler

- Weigh Right PMB-CT Series Piece Count Scale

- Weigh Right Net Weigh Scales

- Ishida Weighing, Filling & Counting Systems

- Weighing & Counting Equipment

At a Glance

- Weighs and fills 1 to 20 lbs of chopped, shredded, diced, batched and small whole vegetables

- Open frame design allows direct access to all contact parts making changeovers a snap

- Non-proprietary wash down touch pad controls

Buy your VFFS film from us, and get a discount on this Weigh Right weigh scale!

Click to enlarge

Recommended

High-Production Fresh Cut Filling Systems

The Weigh Right FCS-1 and the FCS-2 are ideal filling systems to accurately weigh and gently fill fresh-cut or prepared products for food service providers.

These systems weigh and fill 1 to 20 lbs of chopped, shredded, diced, batched and small whole vegetables. Some examples are lettuce, diced onions, stir-fries, cole slaw, chili peppers, celery sticks, florets and more.

Weigh Right fresh-cut filling systems offer high production capacity with either fully or semi-automatic operation.

Constructed of stainless steel for easy cleaning, the FCS-1 and FCS-2 feature an open frame design allowing the operator direct access to all contact parts. This makes changeovers a snap, effectively reducing or even avoiding downtime between runs.

Well suited for a wide variety of products, Weigh Right's fresh-cut systems versatile, delivering consistent results on either low or high-volume runs.

How these Weigh Right Veggie Fillers Work

These Weigh Right FCS systems have a Live Bottom Bin (LBB) to receive product from a spin basket or other source. The LBB has a slow moving conveyor that feeds product first-in-first-out to the incline conveyor which delivers the product at a controlled rate to the scale head.

The product is moved to the weigh bucket using bulk and dribble belts filling 98% of the desired weight quickly and the last 2% at a slow rate using the dribble belt only.

Once accurate weight is reached the product is gently and quickly ushered out by a push plate to ensure a clean discharge into the package.

PMB-1F and PMB-2F Retail Fruit Fillers

The PMB-F will weigh and fill 4 to 40 ounces of fresh-cut fruit into bags, trays or tubs.

Container can be hand placed by an operator or the PMB-F can be designed to fit over and interfaced with an automatic bagger or indexing conveyor to feed into trays or tubs.

Wash down construction, dimpled textured vibratory trays.

Uses non-proprietary wash down touch pad controls to enter desired weight and feed rate.

Products

- Shredded or chopped lettuce products

- Diced onions, tomatoes, carrots or celery

- Small florets, carrot and celery sticks

- Slices carrots, radishes, pickles, potatoes

- Slices pepperoni and fresh cut meats

- Pasta and bean mixes

- Most fresh-cut products of like size, consistency and weight

Options

- Bag take-away delivery system

- Stainless steel mezzanine

- Spouts to suit your bag or container

FCS-1 Specifications

- Electrical: 120 VAC, 1ph, 20amps

- Air: 80psi, 5 cfm

- Dimensions: 182"L x 57"W x 82"H

- Shipping weight: 2,200 lbs

- Live bottom bin: 12 cubic feet

FCS-2 Specifications

- Electrical: 220/120 VAC, 1ph, 20amps

- Air: 80psi, 5 cfm

- Dimensions: 182"L x 57"W x 82"H

- Shipping weight: 4,200 lbs

- Live bottom bin: 45 cubic feet

Weights and Rates of Fresh Vegetable Scales | |||

| FCS-1 | FCS-2 | ||

| Weight | Rate | Weight | Rate |

| 1 lb | 15 fpm | 1 lb | 30 fpm |

| 5 lbs | 12 fpm | 5 lbs | 24 fpm |

| 10 lbs | 18 fpm | 10 lbs | 36 fpm |

| 20 lbs | 5 fpm | 20 lbs | 6 fpm |

Please contact Pro Pac or call 888-318-0083 for your weighing, filling, and counting equipment.