- WEIGH & COUNT

- Weigh Scales

& Counters

- BAG & SEAL

- Vertical Form Fill

& Seal Systems - Flow Wrapping

Machinery - Autobag Bagging

Systems - Baggers & Band Sealers

- LIQUID FILL

- Liquid Filling

Systems - Bottle Management

Systems - Depositors

- TRAY & CARTON

- Tray & Cup Fillers &

Sealers - Carton & Tray Formers

- BROWSE

- ALL CONTRACT

PACKAGING SERVICES - ABOUT QUAL PAC

- QUAL PAC CERTIFICATIONS

& REGISTRATIONS - QUAL PAC LOCATIONS

- Shrink Wrapping

Services - Shrink Bundling

Services - Blister & Clamshell

Packaging Services - Flow Wrapping

Fin Seal Services

nVenia Arpac Brandpac BPMP Shrink Bundling Multi-Packer

- Packaging Equipment and Machines

- Shrink Bundling Equipment

- Polypack Shrink Bundling Systems

- nVenia Arpac Shrink Bundling Equipment

- nVenia Arpac Shrink Bundling Systems

- nVenia Arpac Tray Shrink Bundling Systems

- nVenia Arpac Brandpac Shrink Bundling Systems

- nVenia Arpac Brandpac BPMP Shrink Bundling Multi-Packer

- nVenia Arpac Brandpac BPTS Multi-Pack Shrink Bundler

- nVenia Arpac Brandpac BPTW Tray Bundler

- nVenia Arpac Brandpac BPSW Shingle Wrapper

- nVenia Arpac Heat Shrink Tunnels

- Eastey Shrink Bundling Equipment

- Heat Seal Shrink Bundling Equipment

- Kayat Continuous-Motion Shrink Bundling Equipment

- Shrink Bundling Equipment

At a Glance

- Attractive multi-packs or tray packs for retail display

- Billboard effective print registration

- Recyclable packaging materials

- Cost-effective for material and labor

Buy your shrink bundling film from Pro Pac, and get a discount on this Arpac shrink bundler!

Click to enlarge

Recommended

Continuous-Motion Bottom Overlap Shrink Bundling System

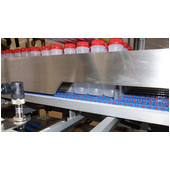

The Brandpac BPMP shrink bundling multipacker is the champion in multi-packing equipment for medium to high-volume food and beverage industries. This versatile continuous-motion bottom overlap shrink wrapping system operates on demand, without a seal bar to shrink wrap up to 75 unsupported multi-packs or trays per minute, depending on the height and weight of the product.

Using single roll print registered polyethylene film, the BPMP-5000 system ensures accurate placement of printed logos, graphics and advertising messages on each bundle with a bull's eye enclosure.

Print registered film provides an attractive forum for your retail marketing message at a fraction of the cost of traditional paperboard packaging. The finished package is an easy to carry multi-pack that is attractive to the consumer.

Servo technology ensures the wrapper provides gentle product handling and precise wrapping. This automatic system accumulates product into patterns, wraps print-registered film around the patterned product and shrinks the film to make multi-packs. The user friendly ARPAC operator interface manages the complete system with simple entry and self diagnostics ensuring reliable performance.

Quick product changeovers take place in less than 15 minutes with the BPMP's pre-programmed product settings, drop-in color coded spacers for infeed lane guides and side film splicer. New product parameters are selected from one of 16 pre-programmed settings.

Features

- Printed film registration for accurate placement of printed graphics

- Heavy-duty frame construction with welded joints for high durability

- Laser cut and CNC machined components for maximum precision

- Powder coat finish provides a durable scratch resistant surface and prevents corrosion

- Fully guarded for safety and easy access

- Gentle product handling with servo or mechanical driven collating system

- Servo or mechanical driven overwrap for smooth and efficient film wrapping

- Servo-driven mechanical film feed is low maintenance and can adapt to a wide range of film lengths (no vacuum)

- Side mounted film rack and film splicing bar for quick and easy film changeover with little or no downtime

- Allen Bradley programmable controller

- Arpac operator interface features a color touchscreen with message display and self-diagnostics

- Low film alert warns that a changeover may soon be necessary

- Easy machine adjustments for reliable and quick product changeover

- Right or left hand operator station and film rack

- Air conditioning standard on main electrical enclosure

Options

- Tray conversion for tool-less changeover from multipack to tray shrink wrapped products

- Machine mounted jib crane to facilitate film loading

- Product turning conveyor

- Wet product seal conveyor extends machine length by 48"

- Side product transfer to infeed extends machine length by 48"

Example Products

- Plastic bottles

- Cans

- Glass jars

- Trays

- Unsupported multi-packs

Product Specifications

- Width (across machine): 6" to 18"

- Length (flow direction): 3" to 12"

- Height Range: 3" to 12"

Film Specifications

- Roll Diameter: Up to 20"

- Gauge: 1.25 to 2.5 mil

- Roll Width: 6" to 26"

- Type: Low density polyethylene

- Clear, print registered or randomly printed film

- Core: Up to 3"

BPMP-5100 Machine Specifications

- Speed: Up to 35 packages per minute

- Electrical: 480 VAC, 3 Ph, 60 Hz, 75 A, 65 kW

- Air: 80 psi, 30 SCFM at 50 CPM

- Machine Length: 311"

BPMP-5200 Machine Specifications

- Speed: Up to 45 packages per minute

- Electrical: 480 VAC, 3 Ph, 60 Hz, 75 A, 65 kW

- Air: 80 psi, 30 SCFM at 50 CPM

- Machine Length: 287"

BPMP-5300 Machine Specifications

- Speed: Up to 60 packages per minute

- Electrical: 480 VAC, 3 Ph, 60 Hz, 97 A, 72 kW

- Air: 80 psi, 30 SCFM at 50 CPM

- Machine Length: 310"

BPMP-5400 Machine Specifications

- Speed: Up to 65 packages per minute

- Electrical: 480 VAC, 3 Ph, 60 Hz, 125 A, 99 kW

- Air: 80 psi, 30 SCFM at 50 CPM

- Machine Length: 410"

Groupers

Groupers for Various Product ShapesArpac designs different groupers to accommodate a variety of product shapes. This assembly is used to separate products into pack groups and control the flow of product into the pacing flight bar assembly. In the case of tray-loaded products, the collator serves to pace and release products into the BPMP-5000.

- Servo Adjustable Starwheel

- 15 minute changeover

- Accommodates round products only

- Servo Adjusted Side Belt

- 10 minute rapid changeover

- Accommodates round products only

- Tool-less servo adjustment of grouper

- Mechanical Adjustable Starwheel

- 45 minute changeover

- Accommodates round products only

- Mechanically Adjusted Side Belt

- 2 hour changeover to replace gripper belts and drive gears

- Accommodates round products only

- Fixed size gripper belt

- Shuttle Grouper

- 30 minute tool-less changeover of grouper

- Accommodates round, non-round and square products

- Lane divider is required for non-round and square products

- Custom Groupers Available

- Our primary focus is finding engineered solutions to your packaging needs

- Many groupers are custom designed to our customer's exact specifications

Please contact Pro Pac or call 888-318-0083 for your shrink bundling equipment.

Product Groupers | |||||

| Model | Mechanical AdjustableStarwheel | Servo AdjustableStarwheel | Servo AdjustableSide Belt | ShuttleGrouper | CustomAvailable |

| BPMP-5100 | X | X | |||

| BPMP-5200 | X | X | X | X | |

| BPMP-5300 | X | X | X | X | |

| BPMP-5400 | X | X | X | X | |