- WEIGH & COUNT

- Weigh Scales

& Counters

- BAG & SEAL

- Vertical Form Fill

& Seal Systems - Flow Wrapping

Machinery - Autobag Bagging

Systems - Baggers & Band Sealers

- LIQUID FILL

- Liquid Filling

Systems - Bottle Management

Systems - Depositors

- TRAY & CARTON

- Tray & Cup Fillers &

Sealers - Carton & Tray Formers

- BROWSE

- ALL CONTRACT

PACKAGING SERVICES - ABOUT QUAL PAC

- QUAL PAC CERTIFICATIONS

& REGISTRATIONS - QUAL PAC LOCATIONS

- Shrink Wrapping

Services - Shrink Bundling

Services - Blister & Clamshell

Packaging Services - Flow Wrapping

Fin Seal Services

nVenia Arpac DPM Intermittent Wrap-Around Case & Tray Packer

- Packaging Equipment and Machines

- Case & Tray Formers & Packers

- Sealed Air Void Reduction Boxing Systems

- Pearson Case Erectors & Tray Formers

- Pearson Robotic Case Packers

- Pearson Bag Inserters & Bag Uncuffers

- A-B-C Case Erectors

- A-B-C Case Packers

- A-B-C Decasers

- A-B-C 70 Partition Inserter

- Adco Tray Formers

- Adco Case Packers

- nVenia Arpac Case Erectors, Case Packers & Tray Loaders

- nVenia Arpac PC-2000 Intermittent Motion Wrap-Around Case Packer

- nVenia Arpac PC-2500 Continuous Motion Wrap-Around Case Packer

- nVenia Arpac PC-3500 & PC-4500 Continuous Motion Wrap-Around Case Packer

- nVenia Arpac TrayStar Continuous Motion Wrap-Around Tray Loader

- nVenia Arpac EL Intermittent Motion End-Load Tray & Case Loader

- nVenia Arpac DPM Intermittent Motion Wrap-Around Case & Tray Packer

- nVenia Arpac MTE Glue Style Tray Erector

- Little David Case Formers

- BestPack Case Erectors

- Polypack TR/TE Tray Former and Loader

- Polypack WR Wrap-Around Case Packer

- Econoseal Case Packers

- Kayat PTF-28 Intermittent Motion Wrap Around Tray & Case Packer

- Case & Tray Formers & Packers

Recommended

Wrap Around Case Packing at 20 Cases per Minute

The nVenia Arpac DPM intermittent motion wrap-around case and tray packers are designed to package a wide variety of products in cases or trays. Reaching speeds up to 25 cases or trays per minute, these rugged machines help minimize labor requirements and increase production output.

By integrating blank feeding, product loading, case forming and container sealing into a single, compact machine, the DPM is ideal for packaging cans, jars, bottles and a host of other products.

Wrap-around case or tray blanks can reduce the amount of corrugated board used by up to 25 percent, with additional savings in warehouse space and lower handling costs.

Tightly wrapped cases and trays enhance stacking strength and help reduce damage caused by products shifting during shipping and handling. If additional strength is required, partitions may be inserted into the case or tray.

Arpac's DPM systems are easily integrated into new lines with other packaging equipment – after cartoners and shrink bundlers, or before tray stackers, shrink wrappers and palletizers.

Features of the Arpac DPM

- Intermittent motion wrap-around case or tray packer

- Combines erecting, loading and sealing into one system

- Speeds up to 20 cycles per minute

- Heavy-duty rugged construction designed for high durability and around-the-clock operation

- Laser cut and CNC machined components for maximum precision

- Baked on powder coat finish provides a durable scratch resistant surface and prevents corrosion

- Allen-Bradley programmable logic controller

- Arpac operator interface with self-diagnostics, cycle counting and system interlocks

- Digital controls for fast and accurate setup when changing product size

- Designed to integrate with custom line controls

- Crank adjustable blank feed with precision scales for easy setup

- Zero clearance systems form a tight package, transforming a flat board to a wrap-around case/tray for superior product protection

- Electrically interlocking guards and control box doors

- Squaring compression for tidy package appearance

- Durable Intralox conveyor eliminates tracking problems

- Nordson ProBlue hot melt adhesive system for superior application flexibility and adhesion

- NEMA 12 electrical cabinet and controls

- Low blank alert

- Central point lubrication simplifies routine maintenance

Options

- Standard and customized infeeds

- Servo-operated drop zone

- Vacuum platen for electric turbine vacuum generator (No compressed air)

- Magnetic platen

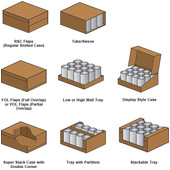

- FOL (Full OverLap) instead of RSC (Regular Slotted Case)

- Crank adjustable lanes

- Extended hopper

Example Applications

- Bottles

- Glass jars

- Brick packs

- Bags

- Cans

- Multi-packs

- Grease tubes

- Cartons

- Boxes

- Tubs

Case Sizes

- Width (across machine): 9" to 20"

- Length (flow direction): 5" to 14"

- Height: 3" to 10"

Tray Sizes

- Width (across machine): 9" to 20"

- Length (flow direction): 7" to 14"

- Height: 3" to 10"

- Wall Height: 1.5" to 10"

Corrugate Requirements

- B or C flute corrugation

- Burst strength: 150 or 200 lb per square inch

- Balanced outside and inside liners to avert warped blanks

- Minimum combined weight facings: 98 lb per square inch

- Maximum 0.25" warp over 12" corrugated surface

Glue Type

- Food grade hot melt adhesive

- Transparent, odorless, granulated

- 0.5 – 1 second set time

- Ejected at 300º to 350ºF (160º to 180º C)

Machine Specifications

- Speed: Up to 20 cases / trays per minute

- Electrical: 230 or 460V, 3Ph, 60Hz

- Air: 80 psi, 20 CFM