- WEIGH & COUNT

- Weigh Scales

& Counters

- BAG & SEAL

- Vertical Form Fill

& Seal Systems - Flow Wrapping

Machinery - Autobag Bagging

Systems - Baggers & Band Sealers

- LIQUID FILL

- Liquid Filling

Systems - Bottle Management

Systems - Depositors

- TRAY & CARTON

- Tray & Cup Fillers &

Sealers - Carton & Tray Formers

- BROWSE

- ALL CONTRACT

PACKAGING SERVICES - ABOUT QUAL PAC

- QUAL PAC CERTIFICATIONS

& REGISTRATIONS - QUAL PAC LOCATIONS

- Shrink Wrapping

Services - Shrink Bundling

Services - Blister & Clamshell

Packaging Services - Flow Wrapping

Fin Seal Services

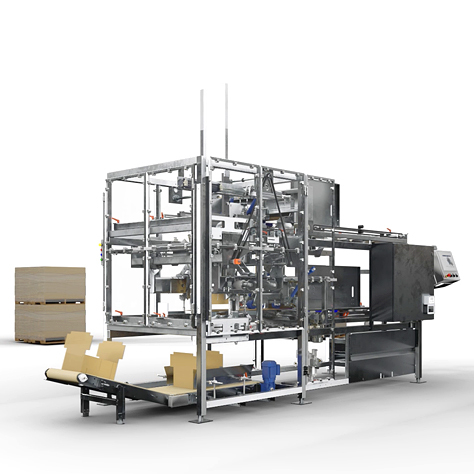

Pearson BF25 Bliss Former

- Packaging Equipment and Machines

- Case & Tray Formers & Packers

- Sealed Air Void Reduction Boxing Systems

- Pearson Case Erectors & Tray Formers

- Pearson Robotic Case Packers

- Pearson Bag Inserters & Bag Uncuffers

- A-B-C Case Erectors

- A-B-C Case Packers

- A-B-C Decasers

- A-B-C 70 Partition Inserter

- Adco Tray Formers

- Adco Case Packers

- nVenia Arpac Case Erectors, Case Packers & Tray Loaders

- Little David Case Formers

- BestPack Case Erectors

- Polypack TR/TE Tray Former and Loader

- Polypack WR Wrap-Around Case Packer

- Econoseal Case Packers

- Kayat PTF-28 Intermittent Motion Wrap Around Tray & Case Packer

- Case & Tray Formers & Packers

Recommended

Produce Extra-Strong Corrugated Shipping and Display Containers

The Pearson BF25 Bliss Former produces extra-strong corrugated shipping and display containers with an H-divider at rates of up to 25 bliss boxes per minute. Advanced features such as high-visibility machine status lighting, non-contact interlocks, CAT-3 Safety Circuits and an easily accessible grace port are standard on the machine.

Fully automatic and ruggedly built to withstand the rigors of high-volume operations, Pearson BF25 bliss formers produce high stacking strength, corrugated shipping and display containers with an H-Divider securely glued to a bliss body wrap. Optional high-capacity automatic stack transfer systems, and a high-capacity adhesive feeder are available for high-speed operations.

Features

Reliable Infeed: Gravity fed magazine ensures that each blank is in proper position for picking without having to worry about proper angles and placement of boards.

Higher Speed: Cases are formed around a static mandrel, which allows higher speeds by removing the necessity of a reciprocating mandrel.

Reliable Glue Compression and Square Cases: The active forming section ensures consistent glue compression by impacting the gluelines as opposed to squeegee/smeared.

Small Footprint: Vertical case forming eliminates having to reposition the orientation of the box for introduction onto the customer's conveyor resulting in a smaller footprint of the machine.

Toolless Changeover Supported by User-Centric HMI: Changeovers are supported by the industry's most advanced HMI with an uncluttered design, intuitive navigation, interactive changeover and fault-recovery guides, live sensor maps, and advanced maintenance features. Scales, pointers and quick release handles ensure additional tools are not necessary. A trained technician can complete a changeover in under 45min.

Highly Reliable Non-Contact Interlocks: Eliminates misalignment of guard door interlocks which prevents problems common to keyed interlocks.

High-Visibility Machine Status: A standard four-light LED beacon and multi-color interior machine lighting provides high-visibility of machine status.

Safety Redundancy with CAT 3: Dual channel safety circuit maintains integrity of safety features in case of single component failure.

Easily Accessible Grace Port: Grace ports provide convenient communication access and 110V convenience outlet at the outside of the machine’s electrical cabinet.

Convenient Dual Access to the Machine: A remote operator station enables machine control on both sides of the conveyor.

Remote Access Capability: Allows Pearson’s support team on-demand access to the equipment's PLC and HMI through a secure VPN connection via an eWON router (ISECOM STAR and ISO27001 certified) to support emergency troubleshooting and reduce on-site visits.

Options

- Air conditioner

- Exit conveyor

- H-divider floor lift

- High-capacity stack transfer system

- High-capacity adhesive feeder

- Low temperature environment

- Plant level ethernet connection

- Powered scoring wheels

Please contact Pro Pac or call 888-318-0083 for your bliss formers.

Specifications | |

| Speed | Up to 25 cases/min Speed depends on bliss size |

| Min. Case Size | 9"L x 8"W x 5"H Extended case size range available |

| Max. Case Size | 25"L x 25"W x 14"H Extended case size range available |

| Sealing | Hot melt glue |

| Changeover | Manual, supported by HMI graphical guided instructions and changeover map, scales, pointers, and quick release handles 45 min (estimate for trained technician) |

| Construction | Low Pressure Washdown Mild Steel Stainless Steel |

| Machine Size Range (ft) | 14'L x 7'W x 11'H |

| Controls | Allen-Bradley CompactLogix PLC PackML Compliant PanelView Color HMI |

| Air Requirements | 80 PSI |

| Power Requirements | 460 VAC |

| Disconnect Sizes | 60 Amps |

| Air Consumption | 1.957 SCF/Cycle |

| FLA (Full Load Amp) of Base Machine | 35 Amps |

| Case Support | Bliss H shipper |

Please contact Pro Pac or call 888-318-0083 for your bliss formers.