- WEIGH & COUNT

- Weigh Scales

& Counters

- BAG & SEAL

- Vertical Form Fill

& Seal Systems - Flow Wrapping

Machinery - Autobag Bagging

Systems - Baggers & Band Sealers

- LIQUID FILL

- Liquid Filling

Systems - Bottle Management

Systems - Depositors

- TRAY & CARTON

- Tray & Cup Fillers &

Sealers - Carton & Tray Formers

- BROWSE

- ALL CONTRACT

PACKAGING SERVICES - ABOUT QUAL PAC

- QUAL PAC CERTIFICATIONS

& REGISTRATIONS - QUAL PAC LOCATIONS

- Shrink Wrapping

Services - Shrink Bundling

Services - Blister & Clamshell

Packaging Services - Flow Wrapping

Fin Seal Services

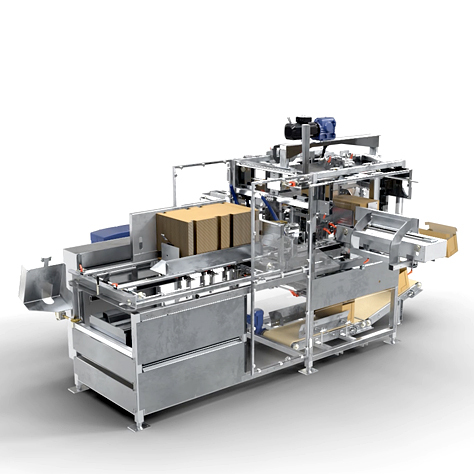

Pearson BF30 Bliss Former

- Packaging Equipment and Machines

- Case & Tray Formers & Packers

- Sealed Air Void Reduction Boxing Systems

- Pearson Case Erectors & Tray Formers

- Pearson Robotic Case Packers

- Pearson Bag Inserters & Bag Uncuffers

- A-B-C Case Erectors

- A-B-C Case Packers

- A-B-C Decasers

- A-B-C 70 Partition Inserter

- Adco Tray Formers

- Adco Case Packers

- nVenia Arpac Case Erectors, Case Packers & Tray Loaders

- Little David Case Formers

- BestPack Case Erectors

- Polypack TR/TE Tray Former and Loader

- Polypack WR Wrap-Around Case Packer

- Econoseal Case Packers

- Kayat PTF-28 Intermittent Motion Wrap Around Tray & Case Packer

- Case & Tray Formers & Packers

At a Glance

- Up to 30 cases per minute

- Active forming section and positive glue compression

- Powered end panel magazines

Buy your boxes from us, and get a discount on this Pearson bliss former!

Click to enlarge

Recommended

Assemble Sturdy Shipper and Display-Ready, Three-Piece Bliss Box Designs

The Pearson BF30 Bliss Former assembles a wide variety of sturdy shipper and display-ready, three-piece bliss box designs at rates up to 30 cases per minute. The BF30 is optimal for larger boxes. A separate model, the BF30-2PB assembles two-piece boxes, ideal for Bag-in-Box applications. For high-speed operations, an optional high-capacity Automatic Stack Transfer System is available. Advanced features such as high-visibility machine status lighting, non-contact interlocks, CAT-3 Safety Circuits and an easily accessible grace port are standard on the machine.

Pearson BF30 bliss formers form a wide variety of shipper and display-ready 3-piece bliss box designs. Using field proven technologies in controls, pneumatics, vacuum systems, and motion, these machines produce boxes at speeds up to 30 per minute. End panel and body wrap vacuum feed systems reduce down time and material waste. For high-speed operations, an optional high-capacity automatic stack transfer system is available.

Features

Proper Positioning of Blanks: Gravity fed magazine ensures that each blank is in proper position for picking without having to worry about proper angles and placement of boards.

Reliable Infeed: Gravity fed magazine ensures that each blank is in proper position for picking without having to worry about proper angles and placement of boards.

Reliable Glue Compression and Square Cases: The active forming section ensures consistent glue compression by impacting the gluelines as opposed to squeegee/smeared.

Small Footprint: Vertical case forming eliminates having to reposition the orientation of the box for introduction onto the customer's conveyor resulting in a smaller footprint of the machine.

Toolless Changeover Supported by User-Centric HMI: Changeovers are supported by the industry's most advanced HMI with an uncluttered design, intuitive navigation, interactive changeover and fault-recovery guides, live sensor maps, and advanced maintenance features. Scales, pointers and quick release handles ensure additional tools are not necessary. A trained technician can complete a changeover in under 45min.

Highly Reliable Non-Contact Interlocks: Eliminates misalignment of guard door interlocks which prevents problems common to keyed interlocks.

High-Visibility Machine Status: A standard four-light LED beacon and multi-color interior machine lighting provides high-visibility of machine status.

Safety Redundancy with CAT 3: Dual channel safety circuit maintains integrity of safety features in case of single component failure.

Easily Accessible Grace Port: Grace ports provide convenient communication access and 110V convenience outlet at the outside of the machine’s electrical cabinet.

Convenient Dual Access to the Machine: A remote operator station enables machine control on both sides of the conveyor.

Remote Access Capability: Allows Pearson's support team on-demand access to the equipment's PLC and HMI through a secure VPN connection via an eWON router (ISECOM STAR and ISO27001 certified) to support emergency troubleshooting and reduce on-site visits.

Options

- Air conditioner

- Custom case range

- Extended end panel magazine

- High-capacity stack transfer system

- High-capacity adhesive feeder

- Low temperature environment

- Plant level ethernet connection

Please contact Pro Pac or call 888-318-0083 for your bliss formers.

Specifications | |

| Speed | Up to 30 cases/min Speed depends on bliss size |

| Min. Case Size | 8"L x 8"W x 4"H Extended case size range available |

| Max. Case Size | 24"L x 24"W x 12"H Extended case size range available |

| Sealing | Hot Melt Glue |

| Changeover | Manual, supported by HMI graphical guided instructions and changeover map, scales, pointers, and quick release handles 45 min (estimate for trained technician) |

| Construction | Low pressure washdown Mild steel Stainless steel |

| Machine Size Range (ft) | 13.5 - 16.8'L x 12.1 - 14.8'W x 9.5 - 10.1'H |

| Controls | Allen-Bradley CompactLogix PLC PackML Compliant PanelView Color HMI |

| Air Requirements | 80 PSI |

| Power Requirements | 460 VAC |

| Disconnect Sizes | 30 Amps |

| Air Consumption | 2.046 SCF/Cycle |

| FLA (Full Load Amp) of Base Machine | 20 Amps |

| Case Support | Bliss shipper |

Please contact Pro Pac or call 888-318-0083 for your bliss formers.