- WEIGH & COUNT

- Weigh Scales

& Counters

- BAG & SEAL

- Vertical Form Fill

& Seal Systems - Flow Wrapping

Machinery - Autobag Bagging

Systems - Baggers & Band Sealers

- LIQUID FILL

- Liquid Filling

Systems - Bottle Management

Systems - Depositors

- TRAY & CARTON

- Tray & Cup Fillers &

Sealers - Carton & Tray Formers

- BROWSE

- ALL CONTRACT

PACKAGING SERVICES - ABOUT QUAL PAC

- QUAL PAC CERTIFICATIONS

& REGISTRATIONS - QUAL PAC LOCATIONS

- Shrink Wrapping

Services - Shrink Bundling

Services - Blister & Clamshell

Packaging Services - Flow Wrapping

Fin Seal Services

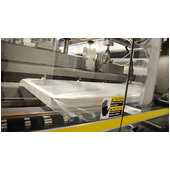

nVenia Arpac 125 Shrink Bundler for Oversized Products

- Packaging Equipment and Machines

- Shrink Bundling Equipment

- Polypack Shrink Bundling Systems

- nVenia Arpac Shrink Bundling Equipment

- nVenia Arpac Shrink Bundling Systems

- nVenia Arpac 55GI Continuous Shrink Bundling System for Printed Goods

- nVenia Arpac 75GI Continuous Shrink Bundling System for Printed Goods

- nVenia Arpac 105 Shrink Bundling System for Oversized Products

- nVenia Arpac 125 Shrink Bundling System for Oversized Products

- nVenia Arpac 108 Shrink Bundling System for Construction Industry

- nVenia Arpac 708HB Shrink Bundling System for the Health / Beauty

- nVenia Arpac 708HB-32 Dual Lane Shrink Bundling System, Health/Beauty

- nVenia Arpac 737C Manual Shrink Bundling Machine

- nVenia Arpac AGR Shrink Bundling System for Dairy Products

- nVenia Arpac Tray Shrink Bundling Systems

- nVenia Arpac Brandpac Shrink Bundling Systems

- nVenia Arpac Heat Shrink Tunnels

- nVenia Arpac Shrink Bundling Systems

- Eastey Shrink Bundling Equipment

- Heat Seal Shrink Bundling Equipment

- Kayat Continuous-Motion Shrink Bundling Equipment

- Shrink Bundling Equipment

At a Glance

- Designed for large products and very wide film

- Built for stacks of pizza boxes, windows, doors, wall panels

- Optional side seal and trim

Buy your shrink bundling film from Pro Pac, and get a discount on this Arpac shrink bundler!

Click to enlarge

Recommended

Shrink Bundle Large Products Such as Pizza Boxes and Windows

nVenia Arpac 125 shrink bundlers are designed to handle large stacks of products with a bull's-eye enclosure. An optional side seal mechanism creates packages with a full enclosure for increased product protection during distribution.

Typical applications include: stacks of pizza boxes, windows, doors, ceiling tiles, floor mats, wall panels and much more.

Operation

- The system operation begins when product is delivered onto the infeed conveyor.

- Product is conveyed and transferred through the film.

- The correct amount of film is released which surrounds the product, the seal bars are closed, and the film is cut and sealed.

- After the film is sealed, product is passed onto the customer conveyor.

Features

- Heavy-duty rugged construction designed for durability and around-the-clock operations

- Laser cut and CNC machined components for maximum precision

- Powder coat finish that provides a durable scratch resistant surface and prevents corrosion

- Handles both bull's eye and side seal enclosures

- Oversized to run maximum film width up to 89"

- Integrated dual stage shrink tunnel

- Top and bottom film racks

- Quick product changeovers

- Allen-Bradley programmable logic controller with Arpac standard operator interface

- Digital controls for fast and accurate setup

- NEMA 12 electrical cabinet and controls

- Central point lubrication allows for routine maintenance without stopping production

- Side smoothing rollers

Options

- Product hold down

- Low tension film feed

- Side seal no trim

- Side seal with trim

- Manual or automatic adjustment for side seal

- Product centering device

- System bypass

- Machine mounted jib crane

- Stainless steel

- NEMA 4X electrical cabinet

- Extended tunnel for higher product up to 15" (will reduce speed)

Construction and Safety

- All conveyors sprocket driven eliminating tracking requirements

- Heavy-duty formed steel frame

- Air control system with filter-regulator, lubricator, and plug-in pneumatic valves

- Central lubrication manifold with nylon tubing

- Vertically integrated manufacturing process and expert craftsmanship

- Working areas guarded with clear polycarbonate hinged doors and electrical interlocks

- Frame and components laser cut ensuring the machine is manufactured and assembled to the tightest tolerances and highest precision

Innovative Film Feed System

- Top and bottom film racks accommodating a total of four 14″ diameter rolls of film

- Power driven pinch roller film feed controlled by low inertia film dancers

- Tool-less film supply roll core chucks

Sealing System

- Extended table top infeed conveyor

- Resistive type heating elements

- Quick-change single element seal bar with military type quick disconnect

- Bottom mounted seal bar for operator safety

- High capacity, progressive damping absorbers on seal frame

- Seal bar obstruction sensor

- Enclosure around sealing zone with interlocked switches

Product Specifications

- Width (across machine): 16" to 120"

- Length (flow direction): 10" to 120"

- Height Range: 0.125" to 15"

Machine Specifications

- Speed: Up to 20 bundles per minute, depending on product length or height

- Electrical Power Requirements: 460 VAC, 3 Ph, 60Hz

- Compressed Air Requirements: 80 psi, 15 SCFM

Please contact Pro Pac or call 888-318-0083 for your shrink bundling equipment.