- WEIGH & COUNT

- Weigh Scales

& Counters

- BAG & SEAL

- Vertical Form Fill

& Seal Systems - Flow Wrapping

Machinery - Autobag Bagging

Systems - Baggers & Band Sealers

- LIQUID FILL

- Liquid Filling

Systems - Bottle Management

Systems - Depositors

- TRAY & CARTON

- Tray & Cup Fillers &

Sealers - Carton & Tray Formers

- BROWSE

- ALL CONTRACT

PACKAGING SERVICES - ABOUT QUAL PAC

- QUAL PAC CERTIFICATIONS

& REGISTRATIONS - QUAL PAC LOCATIONS

- Shrink Wrapping

Services - Shrink Bundling

Services - Blister & Clamshell

Packaging Services - Flow Wrapping

Fin Seal Services

nVenia Arpac 708HB Shrink Bundler for the Health / Beauty

- Packaging Equipment and Machines

- Shrink Bundling Equipment

- Polypack Shrink Bundling Systems

- nVenia Arpac Shrink Bundling Equipment

- nVenia Arpac Shrink Bundling Systems

- nVenia Arpac 55GI Continuous Shrink Bundling System for Printed Goods

- nVenia Arpac 75GI Continuous Shrink Bundling System for Printed Goods

- nVenia Arpac 105 Shrink Bundling System for Oversized Products

- nVenia Arpac 125 Shrink Bundling System for Oversized Products

- nVenia Arpac 108 Shrink Bundling System for Construction Industry

- nVenia Arpac 708HB Shrink Bundling System for the Health / Beauty

- nVenia Arpac 708HB-32 Dual Lane Shrink Bundling System, Health/Beauty

- nVenia Arpac 737C Manual Shrink Bundling Machine

- nVenia Arpac AGR Shrink Bundling System for Dairy Products

- nVenia Arpac Tray Shrink Bundling Systems

- nVenia Arpac Brandpac Shrink Bundling Systems

- nVenia Arpac Heat Shrink Tunnels

- nVenia Arpac Shrink Bundling Systems

- Eastey Shrink Bundling Equipment

- Heat Seal Shrink Bundling Equipment

- Kayat Continuous-Motion Shrink Bundling Equipment

- Shrink Bundling Equipment

At a Glance

- Intermittent-motion, stainlees steel contruction

- Built for health, beauty, and pharmaceutical industries

- Up to 30 packages per minute

Buy your shrink bundling film from Pro Pac, and get a discount on this Arpac shrink bundler!

Click to enlarge

Recommended

Right-Angle Intermittent-Motion for Health and Beauty Products

The right-angle intermittent-motion nVenia Arpac 708HB Series shrink bundler is designed specifically for today's pharmaceutical, health and beauty industry. Ultra-compact in design and economical in price, the 708HB bundler is capable of shrink wrapping up to 25 bundles per minute, depending on product specifications. For faster output, this system is available with dual lanes to run up to 50 bundles per minute.

Constructed of stainless steel, the 708HB Series frame is designed for clean operating environments.

Its telescoping tunnel conveyor is designed for fast change of product dead plates and for even transfer of small product from dead plate into the tunnel.

The 708HB Series handles a variety of multi-pack configurations thanks to multi-row collation capabilities and offers a wide range of standard and customized infeeds.

Features

- Compact single-frame stainless steel construction

- Heavy-duty system for around-the-clock operation

- Laser cut and CNC machined components for maximum precision and strength

- Right or left-hand mounted infeed and controls

- Allen-Bradley programmable logic controller

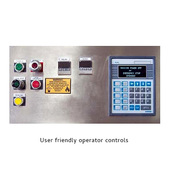

- Arpac operator interface featuring an alphanumeric message display and self-diagnostics

- Simple setup and tool-less changeovers for ease of use and minimal downtime

- Low maintenance conveyor belts do not require tracking adjustments

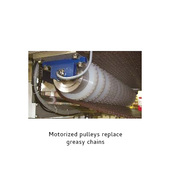

- Motorized pulleys eliminate chain drives and operate more cleanly, with reduced maintenance cost and less noise

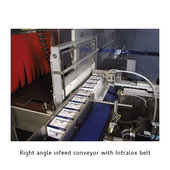

- Single stage right-angle infeed conveyor with Intralox belt

- Telescoping tunnel conveyor

- Bridge plate for small product transfer

- Conveyor elevation 35" +2/-0 for easy integration with existing equipment

- Powered film unwind

- NEMA 12 electrical cabinet and controls

- Low film alert warns that a film changeover will soon be necessary

- Quick-change seal bar with military-type quick disconnect and replaceable plasma coated inserts

- Product hold-down for light products

- Top and bottom film racks accomodate four 14" diameter rolls of film

- Easy to service air cylinders

- Separate pop-up guide and multiple ram stroke programming for multi-row collation

- No lubrication required for clean and easy maintenance

- Levelers for uneven floors

Example Products

- Beauty products

- Vials

- Cosmetics

- Spices

- Glass bottles

- Spray cans

- Boxes

- Plastic bottles

Machine Specifications

- Speed: Up to 20 packages per minute

- Electrical: 208, 230 or 460 VAC, 3 Ph, 60Hz

- Air: 80 psi, 8 SCFM

Product Specifications

- Width (across machine): .75" to 6"

- Length (flow direction): .75" to 11"

- Height Range: .5" to 8"

Film Specifications

- Roll Diameter: Up to 14"

- Gauge: Up to 3 mil

- Roll Width: Up to 15"

- Type: Polyethylene

Please contact Pro Pac or call 888-318-0083 for your shrink bundling equipment.