- WEIGH & COUNT

- Weigh Scales

& Counters

- BAG & SEAL

- Vertical Form Fill

& Seal Systems - Flow Wrapping

Machinery - Autobag Bagging

Systems - Baggers & Band Sealers

- LIQUID FILL

- Liquid Filling

Systems - Bottle Management

Systems - Depositors

- TRAY & CARTON

- Tray & Cup Fillers &

Sealers - Carton & Tray Formers

- BROWSE

- ALL CONTRACT

PACKAGING SERVICES - ABOUT QUAL PAC

- QUAL PAC CERTIFICATIONS

& REGISTRATIONS - QUAL PAC LOCATIONS

- Shrink Wrapping

Services - Shrink Bundling

Services - Blister & Clamshell

Packaging Services - Flow Wrapping

Fin Seal Services

nVenia Arpac 55GI Continuous Motion Shrink Bundler for Printed Goods

- Packaging Equipment and Machines

- Shrink Bundling Equipment

- Polypack Shrink Bundling Systems

- nVenia Arpac Shrink Bundling Equipment

- nVenia Arpac Shrink Bundling Systems

- nVenia Arpac 55GI Continuous Shrink Bundling System for Printed Goods

- nVenia Arpac 75GI Continuous Shrink Bundling System for Printed Goods

- nVenia Arpac 105 Shrink Bundling System for Oversized Products

- nVenia Arpac 125 Shrink Bundling System for Oversized Products

- nVenia Arpac 108 Shrink Bundling System for Construction Industry

- nVenia Arpac 708HB Shrink Bundling System for the Health / Beauty

- nVenia Arpac 708HB-32 Dual Lane Shrink Bundling System, Health/Beauty

- nVenia Arpac 737C Manual Shrink Bundling Machine

- nVenia Arpac AGR Shrink Bundling System for Dairy Products

- nVenia Arpac Tray Shrink Bundling Systems

- nVenia Arpac Brandpac Shrink Bundling Systems

- nVenia Arpac Heat Shrink Tunnels

- nVenia Arpac Shrink Bundling Systems

- Eastey Shrink Bundling Equipment

- Heat Seal Shrink Bundling Equipment

- Kayat Continuous-Motion Shrink Bundling Equipment

- Shrink Bundling Equipment

At a Glance

- Designed for the printing industry

- Built for short stacks, random sized and light-weight bundles

- Up to 55 bundles per minute

- Compact footprint

- Continuous-motion wrapper

- Integrated shrink tunnel

Buy your shrink bundling film from Pro Pac, and get a discount on this Arpac shrink bundler!

Click to enlarge

Recommended

Shrink Bundling for Book Binding and Postal Sequencing

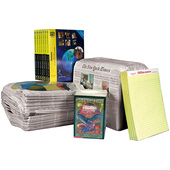

nVenia Arpac industry-leading 55GI shrink bundlers meet the needs of low to medium volume printers and interacts with today's 18,000 to 20,000 books-per-hour binding lines, presorted postal route sequencing applications and the printing industry's fastest counter-stackers.

The Arpac 55GI is capable of wrapping extremely short, lightweight and random sized products, and is ideal for e-commerce applications. Shrink wrapped bundles reduce movement and product damage during shipment, and provide protection against harmful environmental conditions.

The 55GI wraps random sized stacks on demand, without interrupting production of the wrapper itself. The zero tension film feed ensures that this compact and economical shrink bundler wraps up to 55 products per minute.

Operation

- Products are conveyed paced and centered onto the powered infeed conveyor.

- Photo eyes located on the infeed conveyor detect the height of the product as it passes.

- The PLC then cycles the zero tension mechanism so that there is no film tension applied to the product as it intersects the film.

- When the product intersects the film web, it passes through the seal frame and moves onto the seal conveyor.

- As the product moves through the film the machine detects film usage and starts the powered film unwind feeding film.

- After enough film is fed the powered film unwind system stops.

- As the product moves through the seal frame the seal carriage moves the seal frame forward with the product and the seal bars close to form a film sleeve around the tray.

- The seal bars cut and seal the film.

- After the seal dwell timer times out the seal bars open and the seal carriage returns to its home position.

- The product in the film sleeve continues moving forward across the seal conveyor and transfers onto the tunnel conveyor.

- The tunnel conveyor moves the product through the shrink tunnel chamber.

- The film shrinks evenly around the product as it travels through the tunnel.

- When the wrapped product exits the tunnel the film is still somewhat tacky.

- A cooling section located at the exit of the tunnel blows ambient/cool air onto the film as the product passes.

- This cools the film and allows for handling.

- The wrapped product then transfers onto the customer's conveyor completing the shrink packaging cycle.

- Heavy-duty rugged construction designed for high durability and around-the-clock operation

- Compact, single frame design (wrapper with integrated tunnel)

- Laser cut and CNC machined components for maximum precision Powder coat finish

- Speeds up to 55 bundles per minute

- Wraps random sized stacks on demand

- Continuous motion seal head provides smooth and quick transitions of product through the wrapper at high speeds

- Quick change plasma-coated seal bars for long life and easy maintenance

- Timing belt stabilized seal frame reduces maintenance and dirt accumulation

- Independent variable speed drives on the wrapper and tunnel

- Zero tension film feed prevents paper sheets or slippery magazines from shingling

- Side mounted film cradles for quick and easy film loading

- Shrink tunnel with product cooling section at the tunnel exit speeds film curing

- Durable Intralox conveyor belts eliminate tracking problems

- Low film alert warns that a film changeover will soon be necessary

- Allen-Bradley programmable logic controller with ARPAC standard operator interface

- Digital controls for fast and accurate setup

- NEMA 12 electrical cabinet and controls

- Central point lubrication allows for routine maintenance without stopping production

- Books

- Books on pads for e-commerce applications

- Catalogs

- Magazines

- Mailers

- Newspapers

- Paper products

- Periodicals

- Tabloids

- Trays

- Speed: Up to 55 packages per minute

- Electrical: 480 VAC, 3 Ph, 60 Hz, 40 A

- Air: 80 psi, 30 SCFM

- Width (across machine): 5" to 12"

- Length (flow direction): 7" to 18"

- Height Range: .1875" to 10"

- Roll Diameter: Up to 14"

- Gauge: 1.5 to 2.5 mil

- Roll Width: 6 to 19"

- Type: Low density polyethylene (LDPE)

- Clear or randomly printed

- Core: Up to 3"

Features of the 55GI

Example Products

Machine Specifications

Product Specifications

Film Specifications

Please contact Pro Pac or call 888-318-0083 for your shrink bundling equipment.