- WEIGH & COUNT

- Weigh Scales

& Counters

- BAG & SEAL

- Vertical Form Fill

& Seal Systems - Flow Wrapping

Machinery - Autobag Bagging

Systems - Baggers & Band Sealers

- LIQUID FILL

- Liquid Filling

Systems - Bottle Management

Systems - Depositors

- TRAY & CARTON

- Tray & Cup Fillers &

Sealers - Carton & Tray Formers

- BROWSE

- ALL CONTRACT

PACKAGING SERVICES - ABOUT QUAL PAC

- QUAL PAC CERTIFICATIONS

& REGISTRATIONS - QUAL PAC LOCATIONS

- Shrink Wrapping

Services - Shrink Bundling

Services - Blister & Clamshell

Packaging Services - Flow Wrapping

Fin Seal Services

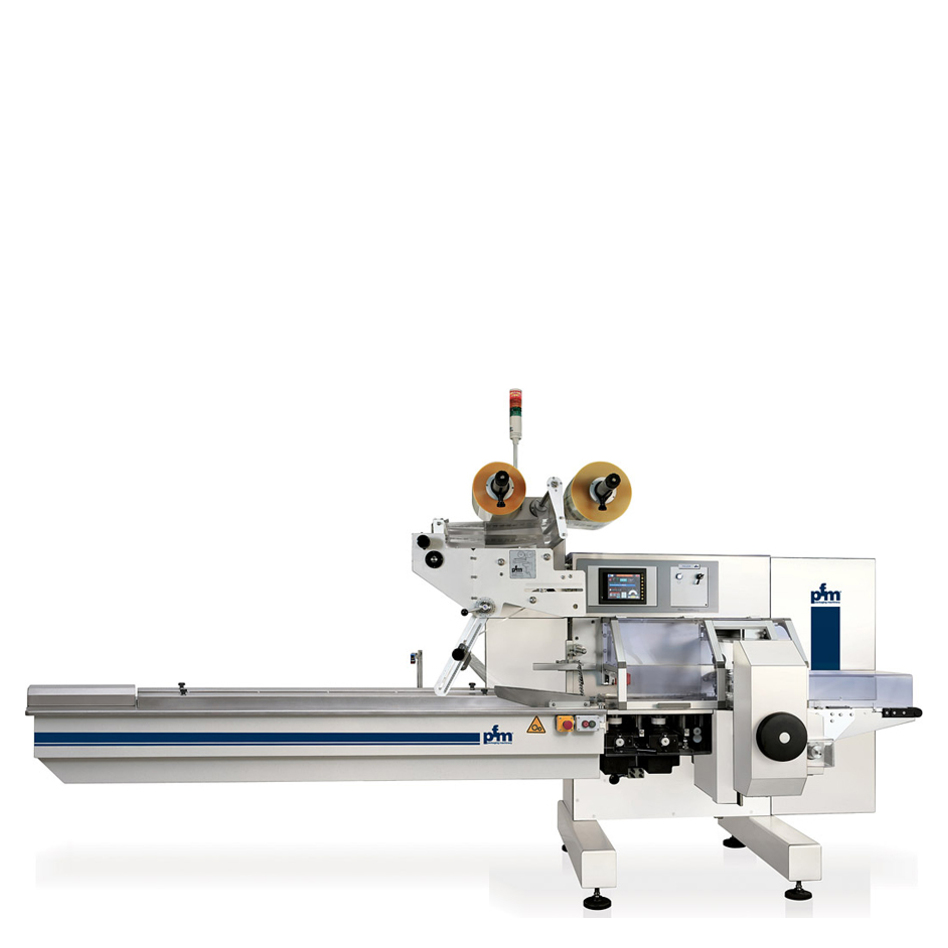

PFM Falcon Horizontal Flow Wrapper

- Packaging Equipment and Machines

- Horizontal Flow Wrapping Equipment

- Redpack Horizontal Flow Wrapping Equipment

- Syntegon Horizontal Flow Wrapping Equipment

- BW Flexible Systems Horizontal Flow Wrapping Equipment

- PFM Horizontal Flow Wrapping Equipment

- PFM BG 2800 Horizontal Flow Wrapper

- PFM BG 4800 Horizontal Flow Wrapper

- PFM Blizzard Horizontal Flow Wrapper

- PFM Blizzard Hard Candy Horizontal Flow Wrapper

- PFM Bora Horizontal Flow Wrapper

- PFM Compact Multi-Pack Horizontal Flow Wrapper

- PFM Falcon Horizontal Flow Wrapper

- PFM Ghibli Horizontal Flow Wrapper

- PFM Hawk Horizontal Flow Wrapper

- PFM Hurricane Horizontal Flow Wrapper

- PFM Mistral BA Horizontal Flow Wrapper

- PFM Mistral BB Horizontal Flow Wrapper

- PFM Pearl Horizontal Flow Wrapper

- PFM Pulsar Horizontal Flow Wrapper

- PFM Scirocco Horizontal Flow Wrapper

- PFM Scirocco Pocket Bag Wrapper

- PFM Shamal Horizontal Flow Wrapper

- PFM Sirio Horizontal Flow Wrapper

- PFM Swift Horizontal Flow Wrapper

- PFM Tornado LD Horizontal Flow Wrapper

- PFM Zephyr Horizontal Flow Wrapper

- Horizontal Flow Wrapping Equipment

At a Glance

- Designed to pillow pack up to 6 products

- Ideal for produce, especially round fruits and vegetables usually packed on trays

- Prevents delicate products from becoming bruised or damaged

- 9 versions for a variety of products

Buy your flow wrapping film from Pro Pac, and get a discount on this PFM flow wrapper!

Click to enlarge

Recommended

Package Up to 6 Products per Package

The PFM Falcon horizontal packaging machine produces pillow-pack type bags from a roll of heat or cold sealable paper or plastic wrapping material. The Falcon's steel monoblock frame structure is painted with three layers of scratch-proof epoxy paint or made of stainless steel. All product contact parts are constructed from 18/10 stainless steel.

Benefits

Multiple Products per Package without Trays

The Falcon versatile format change can produce packs containing 1 to 6 products. Ideal for produce, especially round fruits and vegetables usually packed on trays like apples, kiwis, onions, peaches, etc. Conventional pillow packs can contain 1, 2, or 3 products; 4 (2+2) products; and 6 (3+3) products.

Products previously packed in trays or on trays in pillow bags can now be packed in pillow packs only, reducing packaging costs and simplifying waste disposal.

The infeed conveyor and forming tunnel enable the Falcon to pillow pack products traditionally packaged on vertical packaging machines. The horizontal Falcon prevents delicate products from becoming bruised or damaged.

Ease of Cleaning

The PFM model Falcon has been designed with cantilever principles. By those means all the mechanic and electronic components are placed on the back of the machine in separate and protected areas. Thank to this constructive philosophy the front of the machine is then free from obstacles allowing an absolute easy and quick cleaning operations on all the parts of the machine in contact with the products.

Versatility

The Falcon, being an extremely flexible machine, is able to handle a wide variety of products with absolutely reduced down times for change over to a different format. Falcon is available in 9 different versions to satisfy each and every product and production requirement.

Features

- A double chain infeed conveyor belt is fitted with product carriers and pushers with counter-pitch

- Counter-pitch of pushers can be adjusted by a handwheel to suit the grade of produce

- Vertical guides with idle rollers gently move round, fragile products forward

- The forming box is adjustable to suit differently-sized products

- Small rotating belt fitted at the bottom of the forming box helps insert the product into the wrapping material

- Brush conveyor above the fin seal deck plates gently maintains product position into the film and through the end seal jaws

- Three pairs of separate, tiltable fin seal rollers for the longitudinal seal; the third set also folds the film

- Pneumatically opening fin seal wheels

- Rotary crimpers for crossways sealing maximum diameter 200 mm, with separate temperature control

- Self-centering reel-holder shaft with precise centering adjustment

- Brake equalizing system to maintain consistent braking intensity

- Driven by 5 DC in-line electric motors

- All machine functions are set and controlled through a touch-screen control panel

Available Versions

- Mechanical (basic version)

- Electronic (2 axis)

- Servo touch screen online (3 axis)

- Long dwell high speed

- Extra wide

- Stainless steel (AISI 304)

- Vertical crimper

- Shrink version with trim removal

- Poly version for polyethylene (PE)

Please contact Pro Pac or call 888-318-0083 for your fin seal flow wrapping equipment.