- WEIGH & COUNT

- Weigh Scales

& Counters

- BAG & SEAL

- Vertical Form Fill

& Seal Systems - Flow Wrapping

Machinery - Autobag Bagging

Systems - Baggers & Band Sealers

- LIQUID FILL

- Liquid Filling

Systems - Bottle Management

Systems - Depositors

- TRAY & CARTON

- Tray & Cup Fillers &

Sealers - Carton & Tray Formers

- BROWSE

- ALL CONTRACT

PACKAGING SERVICES - ABOUT QUAL PAC

- QUAL PAC CERTIFICATIONS

& REGISTRATIONS - QUAL PAC LOCATIONS

- Shrink Wrapping

Services - Shrink Bundling

Services - Blister & Clamshell

Packaging Services - Flow Wrapping

Fin Seal Services

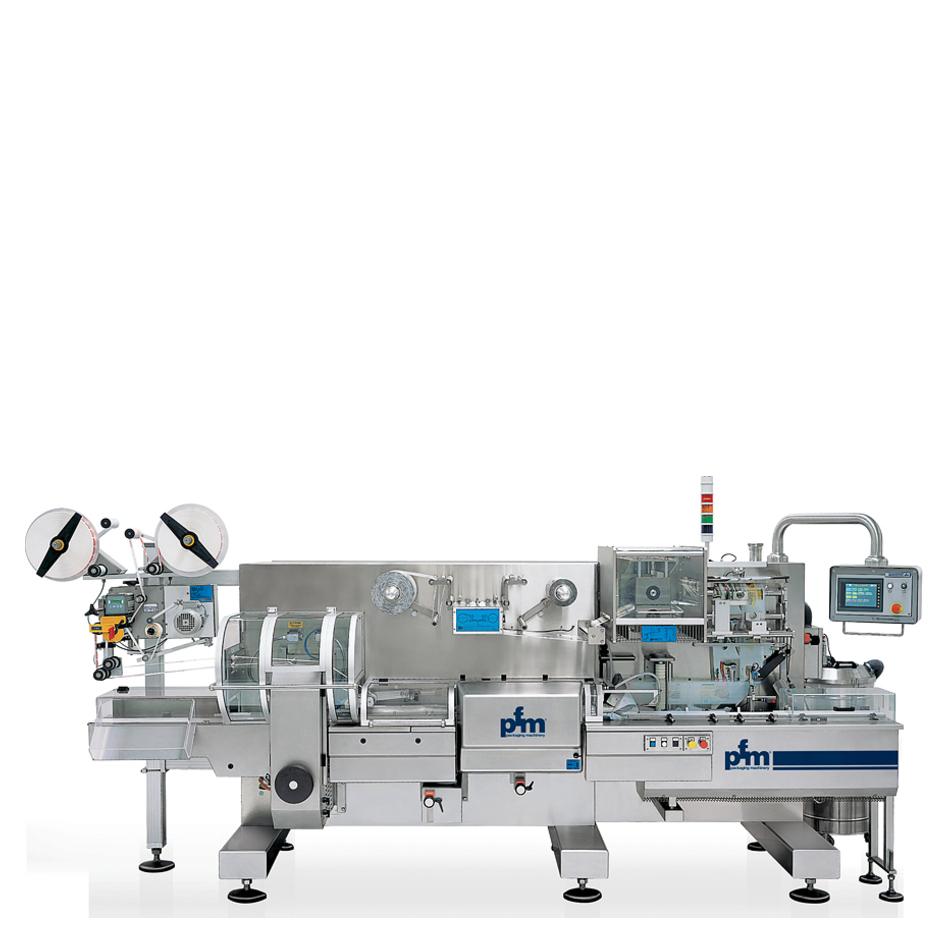

PFM Scirocco Pocket Bag Wrapper

- Packaging Equipment and Machines

- Horizontal Flow Wrapping Equipment

- Redpack Horizontal Flow Wrapping Equipment

- Syntegon Horizontal Flow Wrapping Equipment

- BW Flexible Systems Horizontal Flow Wrapping Equipment

- PFM Horizontal Flow Wrapping Equipment

- PFM BG 2800 Horizontal Flow Wrapper

- PFM BG 4800 Horizontal Flow Wrapper

- PFM Blizzard Horizontal Flow Wrapper

- PFM Blizzard Hard Candy Horizontal Flow Wrapper

- PFM Bora Horizontal Flow Wrapper

- PFM Compact Multi-Pack Horizontal Flow Wrapper

- PFM Falcon Horizontal Flow Wrapper

- PFM Ghibli Horizontal Flow Wrapper

- PFM Hawk Horizontal Flow Wrapper

- PFM Hurricane Horizontal Flow Wrapper

- PFM Mistral BA Horizontal Flow Wrapper

- PFM Mistral BB Horizontal Flow Wrapper

- PFM Pearl Horizontal Flow Wrapper

- PFM Pulsar Horizontal Flow Wrapper

- PFM Scirocco Horizontal Flow Wrapper

- PFM Scirocco Pocket Bag Wrapper

- PFM Shamal Horizontal Flow Wrapper

- PFM Sirio Horizontal Flow Wrapper

- PFM Swift Horizontal Flow Wrapper

- PFM Tornado LD Horizontal Flow Wrapper

- PFM Zephyr Horizontal Flow Wrapper

- Horizontal Flow Wrapping Equipment

At a Glance

- Creates hermetically sealed packages that can be reclosed

- Reduces costs with fewer discards, thinner film, and less maintenance

- Designed for easy cleaning

Buy your flow wrapping film from Pro Pac, and get a discount on this PFM fin seal machine!

Click to enlarge

Recommended

Open and Close

The Scirocco Pocket Bag machine produces packages with both the practicality of being reclosable and the benefit of long-term freshness.

The Pocket Bag machine creates packages with wrapping material made up of one or more layers of film that act as a gas barrier, and may also be stripped off, thereby keeping the package intact.

Marketing Oriented

The Pocket Bag package may be custom printed, including the rear of the package. This capability perfectly combines marketing and information requirements for food products.

Lowering Costs

The PFM Pocket Bag system reduces costs in three ways.

Sealing heavier materials often results in discards due to poor seals. The Pocket Bag machine is designed to use thinner barrier material without compromising the quality of the seals. Running thinner film typically means fewer dicards, resulting in lower costs from less waste.

Thinner film typically costs less than thicker materials. The Pocket Bag system can create perfectly sealed packages with thinner film, lowering your material costs.

Thinner film seals with lower temperatures than thicker films. The reduced temperature of the sealing crimpers results in lower maintenance costs.

Features

- Long Dwell transferring continuous motion transversal sealing system (PFM patent)

- Available with 1, 2, 3 or 4 crimpers per shaft, according to the product and the required speed

- The system guarantees perfectly hermetic seals for up to 200-250 packs per minute

- Servo-Assisted operating system by means of brushless motors in direct electric axis

- Touch screen controls and the possibility of online connection

- Cantilevered machine construction with rounded corners, openable on all sides

- The mechanical and electrical components are housed at the back of the machine

- The front is free from obstruction and quick and easy to clean

- Reel-holding shaft with pneumatic extension and disc brake system

- Automatic film mark reel changing system with no reduction in machine speed

- The sealing units can be removed from the machine in 10 minutes for routine workbench maintenance

- Constructed in AISI 304 stainless steel

Please contact Pro Pac or call 888-318-0083 for your fin seal flow wrapping equipment.