- WEIGH & COUNT

- Weigh Scales

& Counters

- BAG & SEAL

- Vertical Form Fill

& Seal Systems - Flow Wrapping

Machinery - Autobag Bagging

Systems - Baggers & Band Sealers

- LIQUID FILL

- Liquid Filling

Systems - Bottle Management

Systems - Depositors

- TRAY & CARTON

- Tray & Cup Fillers &

Sealers - Carton & Tray Formers

- BROWSE

- ALL CONTRACT

PACKAGING SERVICES - ABOUT QUAL PAC

- QUAL PAC CERTIFICATIONS

& REGISTRATIONS - QUAL PAC LOCATIONS

- Shrink Wrapping

Services - Shrink Bundling

Services - Blister & Clamshell

Packaging Services - Flow Wrapping

Fin Seal Services

PFM Horizontal Flow Wrapping Equipment

- Packaging Equipment and Machines

- Horizontal Flow Wrapping Equipment

- Redpack Horizontal Flow Wrapping Equipment

- Syntegon Horizontal Flow Wrapping Equipment

- BW Flexible Systems Horizontal Flow Wrapping Equipment

- PFM Horizontal Flow Wrapping Equipment

- PFM BG 2800 Horizontal Flow Wrapper

- PFM BG 4800 Horizontal Flow Wrapper

- PFM Blizzard Horizontal Flow Wrapper

- PFM Blizzard Hard Candy Horizontal Flow Wrapper

- PFM Bora Horizontal Flow Wrapper

- PFM Compact Multi-Pack Horizontal Flow Wrapper

- PFM Falcon Horizontal Flow Wrapper

- PFM Ghibli Horizontal Flow Wrapper

- PFM Hawk Horizontal Flow Wrapper

- PFM Hurricane Horizontal Flow Wrapper

- PFM Mistral BA Horizontal Flow Wrapper

- PFM Mistral BB Horizontal Flow Wrapper

- PFM Pearl Horizontal Flow Wrapper

- PFM Pulsar Horizontal Flow Wrapper

- PFM Scirocco Horizontal Flow Wrapper

- PFM Scirocco Pocket Bag Wrapper

- PFM Shamal Horizontal Flow Wrapper

- PFM Sirio Horizontal Flow Wrapper

- PFM Swift Horizontal Flow Wrapper

- PFM Tornado LD Horizontal Flow Wrapper

- PFM Zephyr Horizontal Flow Wrapper

- Horizontal Flow Wrapping Equipment

Pro Pac offers PFM flow wrapping equipment. Each machine in the extraordinarily wide range of PFM horizontal packaging machines is designed to meet the needs of flexible packaging for food and non-food products. These machines have many accessories to customize your packaging process to perfectly package your products.

Please contact Pro Pac or call 888-318-0083 for your horizontal flow wrapping equipment.

Recommended

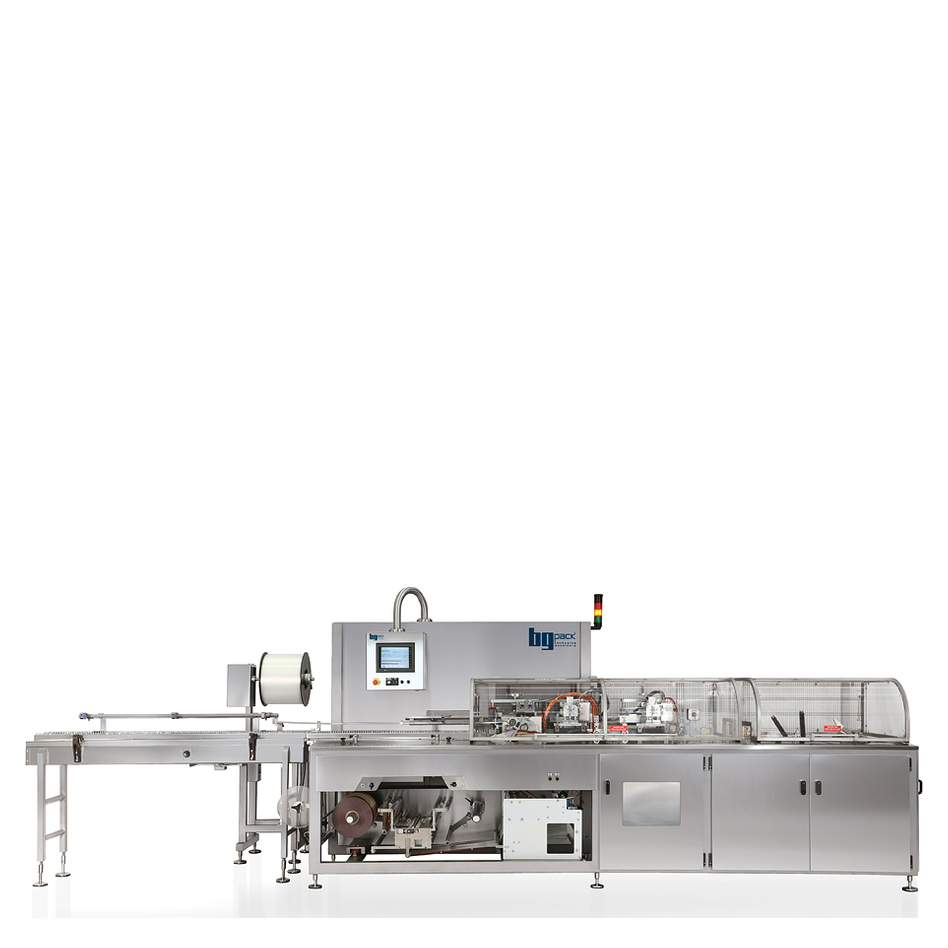

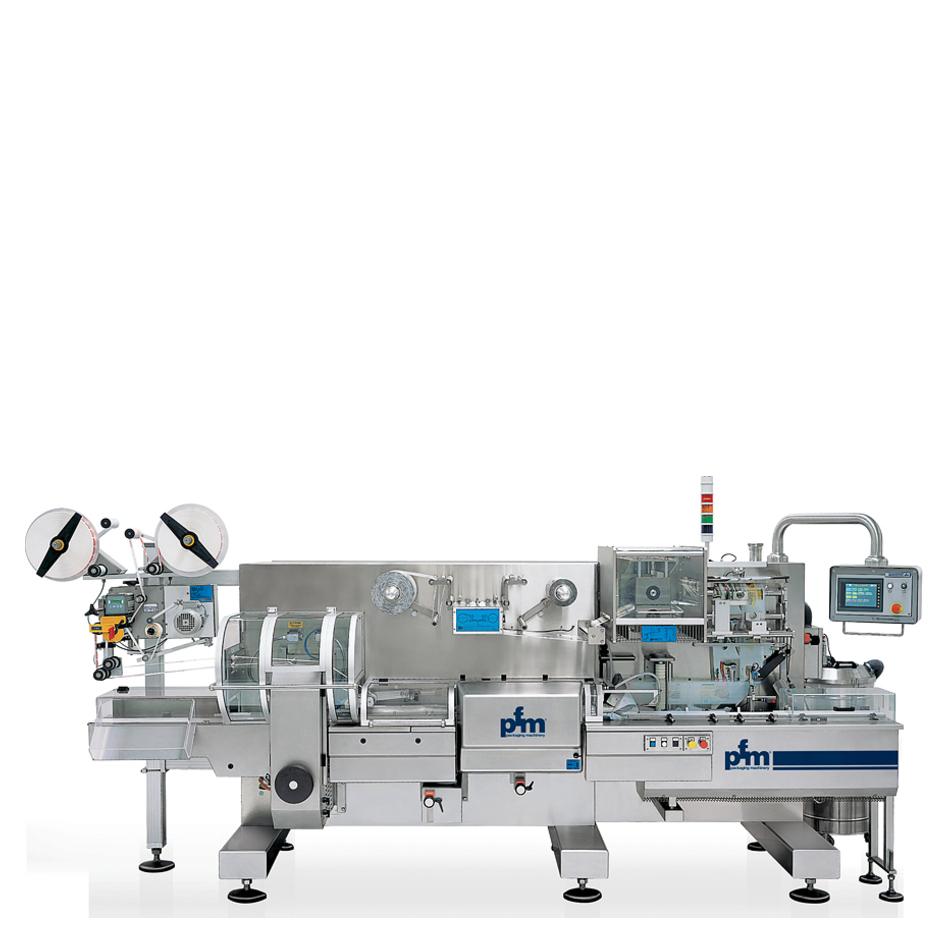

PFM BG 2800 Horizontal Flow Wrapper

The BG 2800 produces flow wrapped packages with three seals that have a perfect appearance. Designed for high speed packaging with Modified Atmosphere Packaging. The BG 2800 creates completely air tight seals, that are compact, smooth, and free from wrinkles.

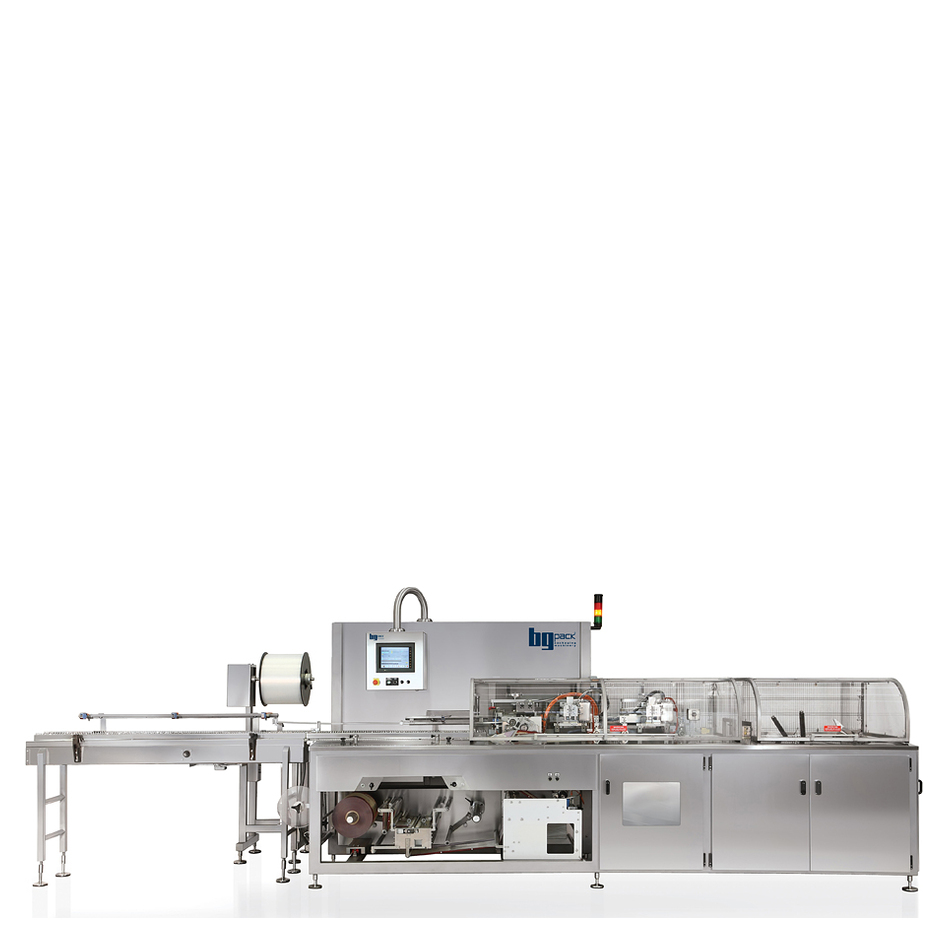

PFM BG 4800 Horizontal Flow Wrapper

The BG 4800 produces flow wrapped packages with three seals that have a perfect appearance. Designed for high speed packaging with Modified Atmosphere Packaging. The BG 4800 creates completely air tight seals, that are compact, smooth, and free from wrinkles.

PFM Blizzard Horizontal Flow Wrapper

The Blizzard super high-speed horizontal flow wrapper packages bubble gum at rates up to 2,000 packages per minute!

PFM Blizzard Hard Candy Horizontal Flow Wrapper

The Blizzard super high-speed horizontal flow wrapper packages hard round, oval, square, and spherical candies at speeds up to 2,000 packages per minute!

PFM Bora Horizontal Flow Wrapper

The PFM Bora modular construction facilitates machine customization and assures complete protection of the internal components.

PFM Compact Multi-Pack Horizontal Flow Wrapper

The PFM Compact produces closed multipacks such as three-seal pillow bags and square bottom stand-up pouches. Ideal for packaging single fragile products.

PFM Falcon Horizontal Flow Wrapper

The Falcon produces pillow-pack type bags from a roll of heat or cold sealable film. Ideal for produce, especially round fruits and vegetables usually packed on trays like apples, kiwis, onions, peaches, etc.

PFM Ghibli Horizontal Flow Wrapper

The Ghibli is a high speed horizontal flow-wrap packaging machine that is designed to package large products and irregular shapes.

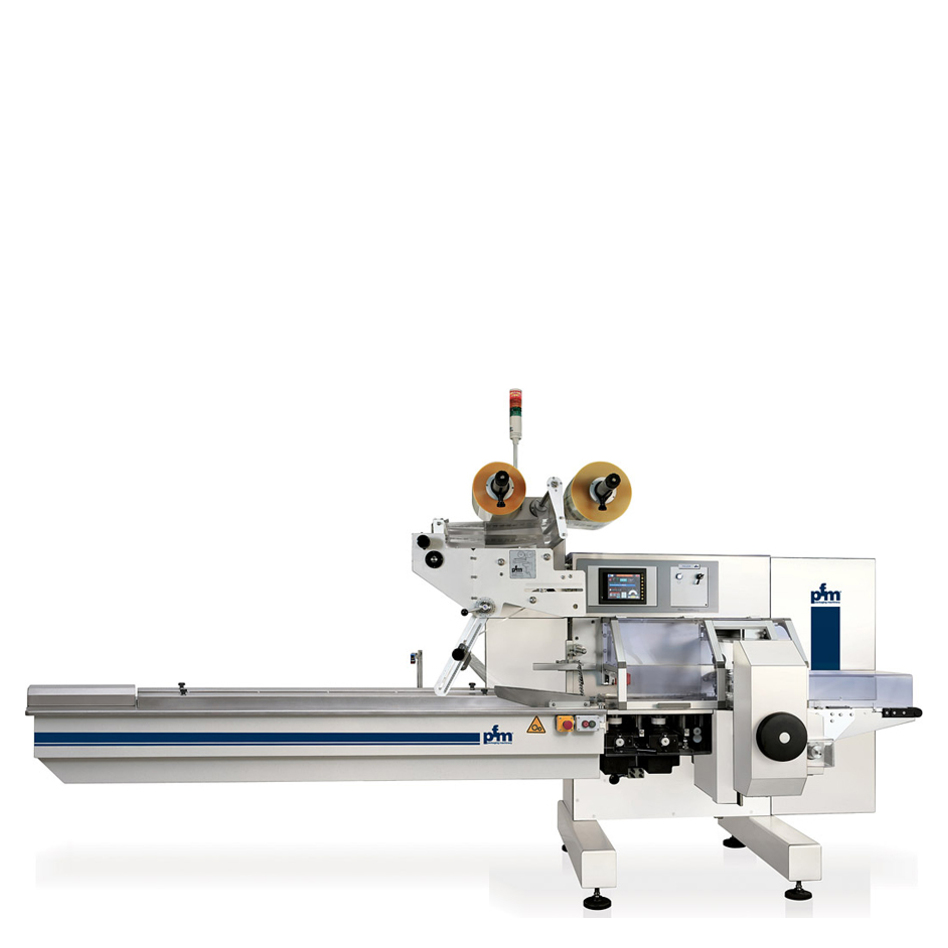

PFM Hawk Horizontal Flow Wrapper

With speeds up to 120ppm, the user-friendly PFM Hawk flow wrapper is ideal for operations demanding top performance, increased flexibility, greater efficiency, and low maintenance costs.

PFM Hurricane Horizontal Flow Wrapper

The special design of the high-speed PFM Hurricane forming box, optimum timer, and rollers for film transfer, the Hurricane wraps products perfectly, producing accurate, crease free seals

PFM Mistral BA Horizontal Flow Wrapper

The Mistral BA horizontal flow wrapper produces high-speed hermetically closed packages from a flat roll of heat sensitive wrapping material. The Mistral BA combines high packaging speeds with hermetic sealing, specifically designed for Modified Atmosphere Packaging (MAP).

PFM Mistral BB Horizontal Flow Wrapper

The PFM Mistral BB horizontal flow wrapping machine uses film positioned in a high position, and is specifically designed to be compatible with Modified Atmosphere Packaging (MAP).

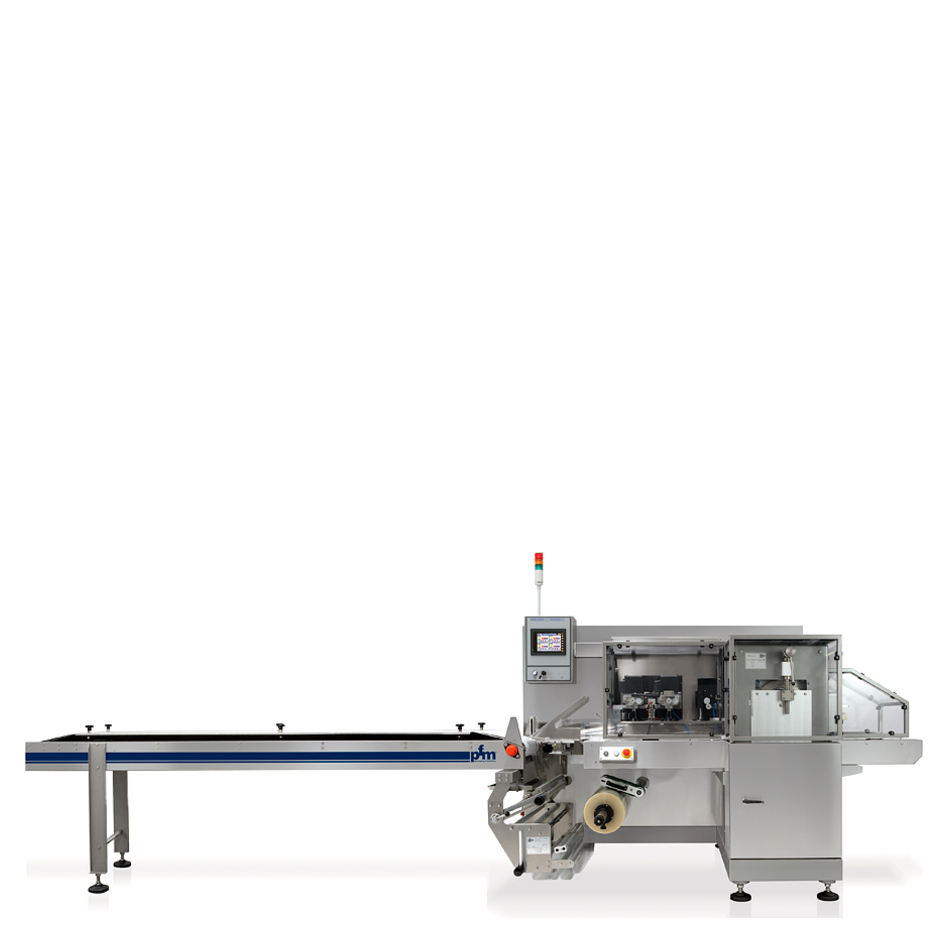

PFM Pearl Horizontal Flow Wrapper

The innovative Pearl is a full servo horizontal flow wrapper that produces pillow-pack style packages from a flat reel of heat sealable wrapping material. The Pearl has sturdy construction with a carbon steel fabricated frame, compact design, cutting edge hardware, and reliable, operator-friendly control software.

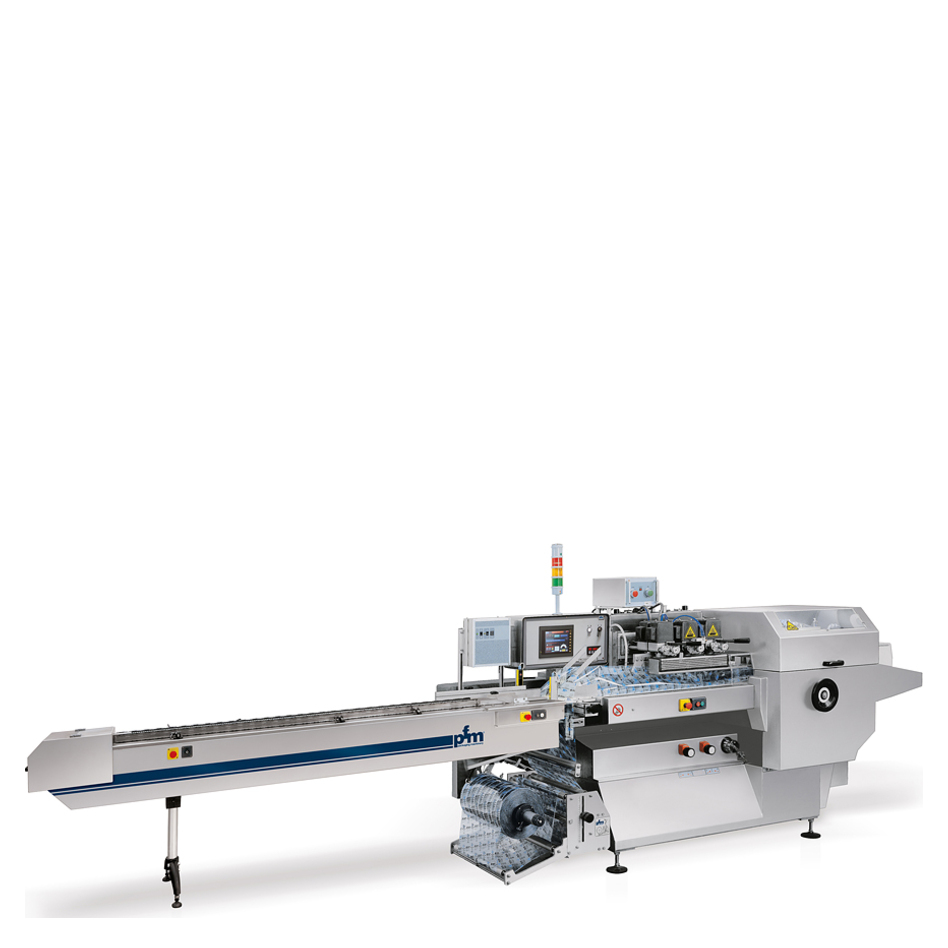

PFM Pulsar Horizontal Flow Wrapper

The PFM Pulsar has been designed to wrap products of different sizes and shapes with its LVA feature for automatic adjustment of package length according to product length. Ideal for green leafy vegetables, pizzas, Christmas cakes, large bologna and salami.

PFM Scirocco Horizontal Flow Wrapper

The Scirocco is a flow pack servo-assisted horizontal wrapping machine for producing packages that are hermetically sealed, perfect for Modified Atmosphere Packaging. The Scirrocco is designed so that all of its parts can be easily cleaned.

PFM Scirocco Pocket Bag Wrapper

The Scirocco Pocket Bag machine produces packages with both the practicality of being reclosable and the benefit of long-term freshness.

PFM Shamal Horizontal Flow Wrapper

Designed for modified atmosphere packaging (MAP), the PFM Shamal horizontal flow pack packaging machine produces air-tight sealed packages in air-tight with three seals.

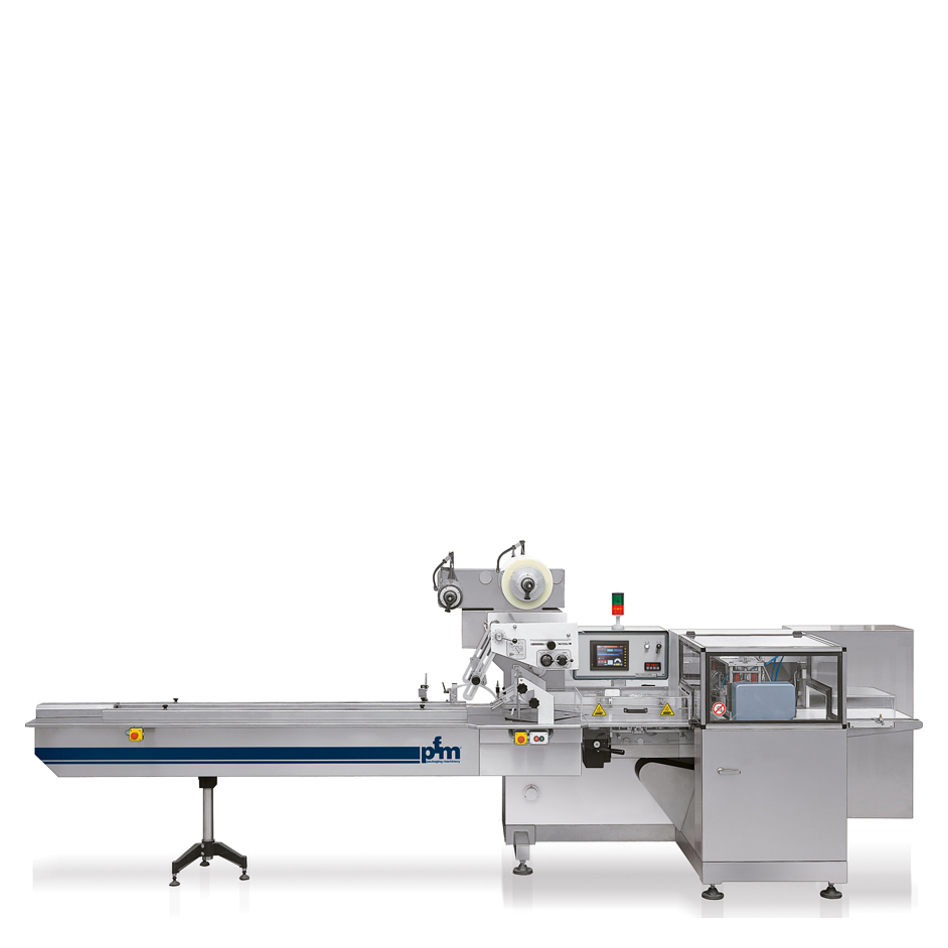

PFM Sirio Horizontal Flow Wrapper

The PFM Sirio full servo horizontal pillow-pack wrapper is specifically designed for the dairy industry, sealing pillow-pack style packs from a flat reel of heat or cold sealable wrapping material.

PFM Swift Horizontal Flow Wrapper

The PFM Swift is a horizontal flow-wrap machine with rotary crimp jaws, designed to wrap at speeds of up to 100 bags per minute.

PFM Tornado LD Horizontal Flow Wrapper

The PFM Tornado LD is a high-speed, long-dwell horizontal flow wrapper produces up to 100 packages per minute with hermetically closed seals, specifically designed for Modified Atmosphere Packaging (MAP).

PFM Zephyr Horizontal Flow Wrapper

The electronic PFM Zephyr is designed to run on multi-shift operations. Built with a cantilevered main frame, the Zephyr completely separates product packaging and drive elements.